CRANEMASTERS SERVICES

Bridge Span Replacement

When contracting with Cranemasters for bridge span replacement, the scope of work typically involves a series of highly specialized activities. Typically, these activities include removing, replacing, and upgrading sections of a bridge to ensure structural integrity, safety, and longevity. Bridge span replacement can be part of routine infrastructure upgrades, emergency repairs, or larger modernization projects.

Project Planning and Permitting

A critical phase involves meticulous planning and obtaining necessary permits from local, state, or federal authorities. This includes:

- Coordinate with stakeholders like transportation departments, utility companies, and local communities.

- Schedule work to minimize disruptions, often requiring nighttime or off-peak hour construction.

- Develop contingency plans for potential challenges, such as weather delays or unexpected structural issues.

Temporary Structural Support

During span replacement, temporary measures are put in place to maintain the bridge’s stability. This includes:

- Shoring and Falsework: Installing temporary supports to bear the load of the bridge during construction.

- Traffic Management Solutions: Creating detours, temporary bridges, or lane diversions to ensure traffic flow while the work is underway.

Span Removal

The removal of the old bridge span is a complex task that often involves:

- Cutting and Dismantling: Using tools like diamond saws, plasma cutters, or hydraulic breakers to carefully dismantle the span.

- Craning and Transport: Employing cranes or other heavy equipment to lift and transport removed sections to a designated area for disposal or recycling.

- Demolition Debris Management: Managing and disposing of materials in an environmentally responsible way.

Span Installation

Installing the new bridge span involves precise execution and coordination. This stage includes:

- Prefabrication of Components: Constructing sections of the new span off-site to expedite the installation process.

- On-Site Assembly: Aligning and securing the new span into place using cranes, hydraulic jacks, and specialized equipment.

- Post-Installation Adjustments: Conducting alignment checks, stress testing, and securing joints and bearings.

Structural Reinforcements and Upgrades

Many bridge span replacement projects involve additional structural upgrades, such as:

- Strengthening support piers or abutments to handle increased loads.

- Replacing bearings and expansion joints for improved flexibility and durability.

- Enhancing guardrails, pedestrian walkways, and barriers.

Commitment to Quality and Safety

Our Strategic Systems OperationsTM follow the highest industry standards.

- We are in full compliance with FMCS, OSHA, MSHA, FRA regulations, and Railroad Safety Certification requirements.

- We evaluate our safety performance weekly, analyzing incident trends and implementing corrective actions.

- We apply strict quality control measures to guarantee the quality and performance of our products and services, meeting long-term expectations as well as regulatory requirements.

Explore Cranemasters Capabilities

Download Capabilities Specifications (PDF)

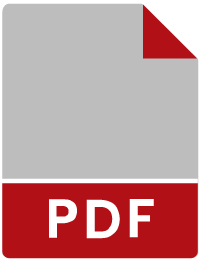

CRANEMASTERS BRINGS QUIET TO THE NEIGHBORHOOD

The Belt Railroad Company of Chicago (BRC) tasked Cranemasters with replacing 56 retarders and tracks to help make the nearby community a quieter place to live.